Pioneer Products Offers the Most Demanding

Machining Solutions Under Budget

Pioneer Products is an IATF certified full service provider of complex machined and assembled pressure tight castings. We specialize in customizing processes and systems to assure customer satisfaction in a short lead-time environment. This includes industry leading engineering, design, construction, and use of state of the art tooling, custom gaging, and pressure test equipment.

As a family owned and operated corporation for over 50 years, Pioneer continues to build our reputation through the strength and success of our employees. We create training and growth opportunities by interactively partnering with local educational institutions to sustain our Tradition of Excellence.

Industries We Service

Engineered Solutions

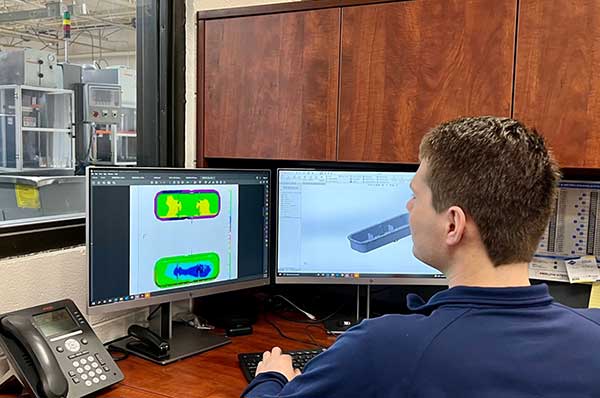

Our skilled engineers have proven problem-solving capabilities.

From operational drawings throughout production, we ensure our engineers and QC personnel will monitor your order each step of the way. We will solve the most demanding machining problems, while keeping design and engineering costs to a minimum.

State-of-the-Art Technology

We have the equipment and capacity to produce your specialty precision components – period.

Investing in advanced production machinery provides our engineers and craftsmen the support required to leverage their talents. Talent combined with technology allows Pioneer Products to continuously improve our processes and production. We never settle and never compromise.

Our People

Our talented team sets us apart from other machine shops.

When our committed craftsmen join Pioneer Products, they thrive and stay here. We are one of the few companies having the range of experiences to assure your project launched with speed and executed with reliability.

Customized Flexibility

For over 50 years we’ve been committed to accepting challenges.

Pioneer Products is a precision CNC machine shop with machining, grinding, plating, heat treating and engineering support for all of your manufacturing needs. Our broad capabilities allow us the versatility to run die cast, perm mold, and sand cast products in both ferrous and nonferrous metals.